Leeds business achieves vital accreditation to meet soaring demand for reusable face shields

A Leeds-based product design specialist which donated vital face shields to frontline health workers at the peak of the COVID-19 crisis, has achieved vital accreditation to help it meet soaring demand for its reusable face shields across the UK.

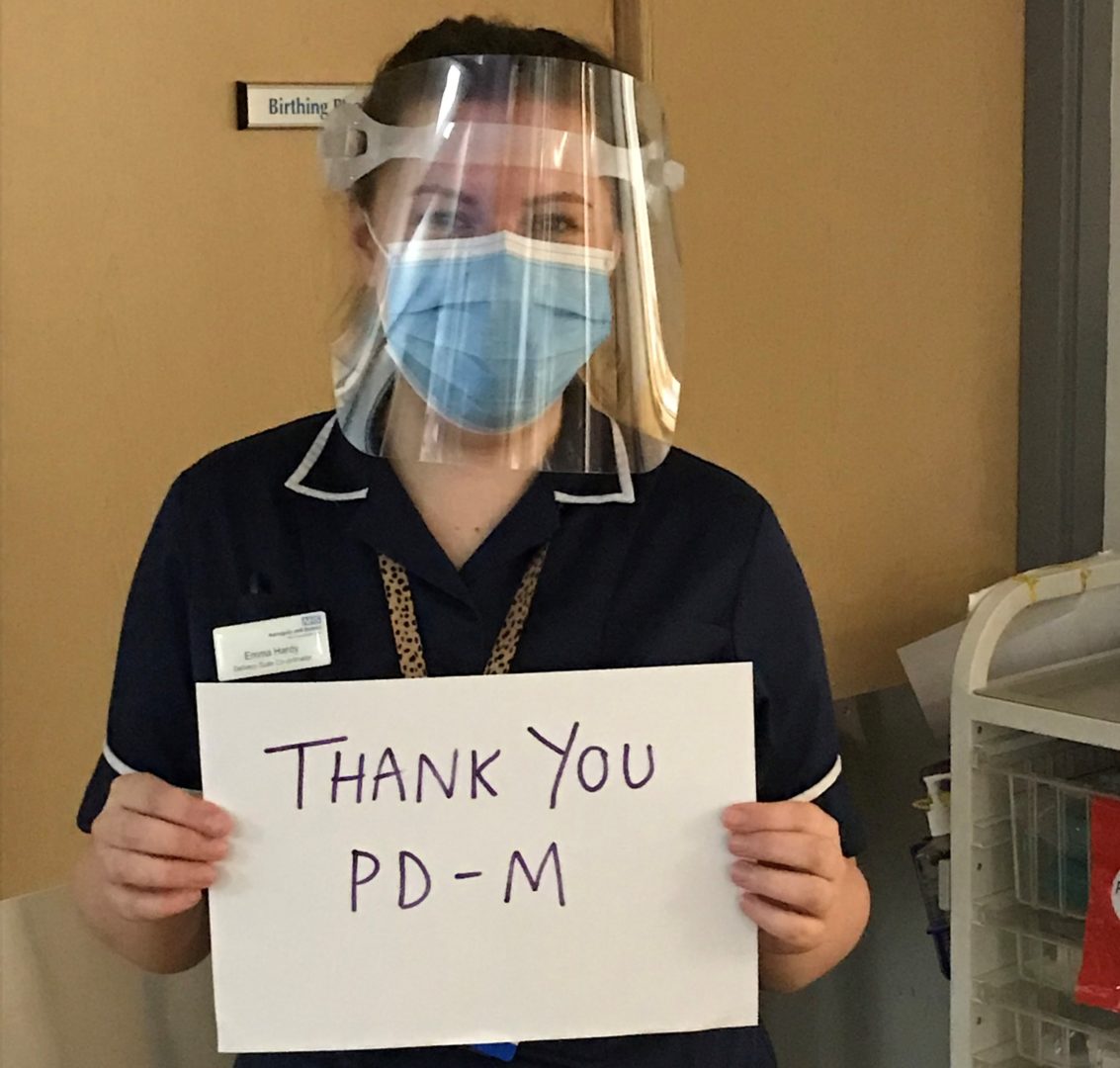

Pd-m International, based at Nexus, used lockdown to focus its design teams on products which would provide vital support for healthcare workers and donated over 1,000 reusable face shields to St James’s Hospital in Leeds and St George’s Hospital in London.

The company has now achieved CE Mark accreditation for the product as it gears up to meet much wider demand for face shields across manufacturing and retail sectors, as well as in education, health and social care environments.

“We were permitted to fast-track production of the face shields, under strict Government guidelines, in order to meet the immediate needs of the COVID-19 crisis,” said Richard Hall, Managing Director of Pd-m.

“Around 70% of our product design business is related to the medical device and life science sectors, so we work very closely with people who were on the frontline during the pandemic. We knew they needed high quality, medical grade face shields, which were safe, easy to wear, reusable and could be manufactured quickly and at scale.

“We worked in close collaboration with senior clinicians at St James’s Hospital to develop our product and were delighted to be able to donate much-needed face shields to frontline staff there and at St George’s Hospital in London.

“Now, as many different businesses start returning to their places of work and need face shields to operate safely and within Government guidelines, we are seeing increased demand from a much wider market. Achieving CE Mark accreditation is vital to meet that demand, giving businesses the assurance that they are using face shields which conform with stringent health, safety and environmental standards.”

Pd-m’s face shields are produced using laser-cutting technology and are lightweight, adjustable to any head shape and easy to clean – simply by washing in soapy water using a soft cloth. They meet stringent regulatory standards, including compliance with other personal protective equipment.

The company’s design specialists are also developing a range of other products to support businesses in creating safer working environments, as staff return to work after the lockdown, including hands-free door openers.

Nexus Director Dr Martin Stow comments: “Pd-m is a perfect example of the focus and innovation we’re seeing from the Nexus community during the current lockdown. Wherever they can, member businesses are developing solutions to the challenges we’re facing and creating products and services which will benefit our society and the UK economy as we emerge from the crisis.”